Answers can be found in the NRCA Manual: Metal Panel and SPF Roof Systems

- What must a designer consider when choosing a metal roof system? Pg. 95

- What are the 2 types of metal panel roof systems? Pg 95

- Architectural metal panel roof systems require what type of substrate? Pg 95

- Is a metal panel roof system considered a water shedding roof system? Pg 95

- Yes

- The seams on a metal panel roof systems are not always watertight. Why is that? Pg 96

- Because it is a water shedding roof system.

- Architectural metal panel roof systems perform well at what slope?

- 3:12 or greater

- What is the minimum underlayment recommended for architectural metal roof panels?

- ASTM D4869 Type III or Type IV (No. 30) asphalt-saturated felt underlayment and separate slip sheet, such as rosin-sized sheathing paper or underlayment with slip-sheet capabilities.

- What are structural metal roof panels?

- Metal roof panels that are used in metal roof panel roofing assemblies have the strength to span joist, purlins etc. without the need of being supported by a continuous or closely spaced roof deck. Structural metal roof panels are usually weatherproof meaning that the seams, end laps, etc. are watertight. Under most circumstances structural metal roof panels do not require underlayment.

- What is the minimum slope recommended for structural metal roof systems?

- ½:12 and sometimes ¼:12

- Why should roof designers consider the valley when considering the minimum slope of a roofing systems?

- Because the valley slope is less than the roof slope.

- Where is the strength of structural metal panels derived from?

- From the panel and seam configuration (ribs) or the use of heavier gauged metal.

- What do structural metal roof panels incorporate in the seams to make them watertight?

- Sealant or an anti-capillary hem.

- What is an anti-capillary hem?

- Can structural metal roof panels be used in architectural applications?

- Yes

- Why would structural metal roof panels

- How are the ribs in structural metal panels profiled?

- With high side ribs and stiffening ribs or intermediate ribs located in the pan.

- Why would structural metal roof panels be used in an architectural application?

- For increased wind-uplift resistance

- What kind of metal is typically used for structural metal panels?

- Galvalume, galvanized steel, stainless steel, or aluminum.

- In addition to Architectural & Structural metal panel roof systems, what are some other categories of metal roof systems?

- Hybrid metal panel roof systems and exposed fastener metal roof systems.

- What is a hybrid metal panel roof system?

- Flat-seam, soldered metal panel roof systems that are weatherproof but still require a continuous or closely spaced structural substrate. They are usually 18 inches by 24 inches.

- What is an exposed fastener metal panel roof system?

- Exposed fastener metal roofs rely solely on the exposed fasteners to be secured to the roof. They don’t use any concealed clips anywhere on the roof. They used to only be used for agricultural purposes but are now commonly used on residential & commercial buildings.

- What is the recommended minimum slope for an exposed fastener metal panel roof system?

- 4:12

- What type of gasket is required on screws for exposed metal panel roof systems?

- An ultraviolet-resistant gasket

- What material is the gasket on a metal roof fastener made of?

- Usually EDPM or other materials that provide UV protection and leak protection.

- What can expansion and contraction of the metal roof panels do the fastener holes?

- It can elongate the metal roof fastener holes.

- What is the minimum exposure to be considered a metal roof panel?

- 3 square feet

- What is the maximum exposure to be considered a metal roof shingle?

- Less than 3 sqft

- Metal panels can be formed from cut sheets or _______ ?

- Coil

- What can a raised rib in a metal panel roof do?

- Accommodate thermal movement, highlight the roof’s aesthetics, facilitate interlocking and seaming, and add structural characteristics to the metal panel.

- Aluminum and copper metal roof panels can be arched with radii as low as how many inches?

- 24

- Steel metal roof panels can be arched with a radii as low as how many inches?

- 60 inches

- When does the curving of metal roof panels usually occur?

- After the fabrication of the panel

- Field curving of metal roof panels allows what?

- It allows curved panels to be fabricated to match a substate curvature.

- Why is it important to consider the seam type for weatherproofing?

- Because curved panels installed on arched roofs will be install below the recommended pitch. The below-minimum pitch occurs near the apexes.

- Where does the below the recommended pitch occur on arched or vaulted roofs?

- Near the apex.

- Are double-lock seams more weatherproof than single-lock seams?

- Yes

- What should designers consider when designing a curved metal panel roof?

- Eave-to-Eave panels are suggested

- Transverse seams should not be located where the pitch is less than 4:12

- The seam type should be appropriate for weather conditions.

- The more complex the roof, the more critical the type of seam for weatherproofing.

- What type of metal panel roof seam is adaptable to many types of surfaces?

- A Flat Seam

- What types of surfaces are metal sheets usually joined with flat seams?

- Conical or curved surfaces or spires, domes or cupolas.

- What is a cupola?

- A hollow frame that protrudes up from the roof.

- What is a spire?

- A tall narrow pointy shaped roof usually at the top of a tower.

- What is a Flat Seam, non-soldered metal panel roof seam?

- A seam where individual flat-pan panels are applied in an overlapped, interlocking shingle fashion.

- What is the minimum fold over for the interlocking seams for a non-soldered flat seam?

- ¾”

- How are the folded seams of a flat seam metal panel secured?

- With a minimum of 2 fasteners.

- Are non-soldered flat seam metal panel roofs weatherproof?

- No, they are water shedding and are used in architectural applications.

- What is a Soldered Flat Seam?

- A soldered flat seam is usually installed on lower sloped roofs to make the system weatherproof. Metals for this application must have the ability to be soldered.

- Metals considered for a soldered flat seam must be solderable. Seam edges should be ________ and ____________ before soldering.

- Fluxed, and Pre-tinned

- For soldering a seam, the metals that require pre-tinning (eg copper), sheet edges should be pre-tinned to a minimum width of _______ inches before folding the edges.

- 1 ½ “

- What is a Standing Seam?

- The term standing seam refers to almost any type of metal panel roof system with a raised vertical seam. But typically it is referred to as those metal panels with seams that interlock or are seamed vertically above the metal roof panel’s pan.

- What type of interlocking, or seaming are there?

- Mechanical or By Hand, single or double locks, snapped or rolled and locked together, which joins together friction-fit components.

- Common friction fit seams are snap-on cap and snap-on batten seams.

- What is the recommended minimum seam height for standing seam?

- 7/8 of an inch

- What is Pre-tinning?

- To coat (a metal) with solder or tin alloy prior to soldering or brazing it.

- What are the four basic panel-to-panel seaming methods?

- Mechanical Seam

- Snap-together seam

- Integral (tough-and-groove) seam

- Hooked seam

- What is a Mechanical Seam?

- A mechanical seam is completed by hand seamers, tongs, or powered seaming devices. These tools turn the seam completely over itself creating a double-locked weatherproof seam.

- What is a snap-lock seam?

- In a snap-lock seam, male and female legs are adjoined to secure the seam in place.

- Why are snap-lock seam metal panel roof systems usually restricted to steep-slope roofs?

- Because they have relatively poor waterproofing?

- What is a snap-on seam?

- A snap-on seam uses a separate rate cap or batten snaps onto a panel’s ribs or clip to complete the seam.

- Why are snap-on seam metal roofs usually only used in steep-slope applications?

- Because they have relatively poor waterproofing.

- What is a hooked seam?

- A hooked seam is a flat-lock, flat seam used in some types of architectural metal systems, such as Bermuda horizontal panels or metal shingles.

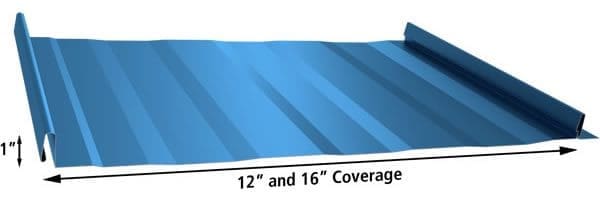

- Metal panel width is range from ____ inches to _____ inches?

- 12, 24

- What should designers consider before using wider metal roof panels?

- Wind resistance, because larger wind uplift forces will be placed on each fastener or clip.

- More potential for oil canning

- Metal panel roof systems can be fabricated where?

- Manufacturing facilities, roofing contractor’s facilities, or at the job sites.

- What are the two methods metal panel roof systems can be fabricated?

- Using coiled metal stock and roll forming equipment

- Using a bending brake to form panels from flat-stock sheet metal.

- Why must special consideration be given to the fastening requirements of a metal panel roof system?

- The fastening substrate must provide adequate anchorage to resist design wind-uplift pressures.

- Regarding movement, the metal panel roof design must accommodate for what?

- Thermal movement or metal panels

- Sliding forces (drag loads)

- What causes thermal movement?

- Changes in temperature

- What causes drag loads?

- Gravity and snow loads.

- To resist drag loads typical metal panel roof systems need to be _____________.

- Fixed, but still allow for thermal movement.

- How can a metal panel be fixed but still allow for thermal movement?

- By providing a fixed point of attachment at either the hip and ridge, or at the eaves and valleys

- Why are fasteners are the hip and ridge more aesthetically appealing?

- Because the fasteners can be concealed under the ridge or hip caps

- When panels are fixed at the ridge they should not be fixed at the __________.

- Valley

- Providing more than one fixed point in a panel can result in what?

- Panel deformation or damage due to thermal movement.

- Regarding metal roofs, what are cleats, clips, and fasteners?

- They are components that secure the metal roof panels and flashing to the decking.

- What are metal roof cleats?

- A continuous metal component installed behind the lead edge of a metal roof accessory, such as coping or edge metal, used to secure the metal accessory to the substrate by a slip joint or crimping the leading edge to the cleat.

- How are cleats anchored?

- With mechanical fasteners to the substrate.

- Why are cleats an aesthetically pleasing way to anchor metal accessories?

- Because they provide a hidden method of anchorage.

- What is a metal roofing clip?

- An individual metal component installed at predetermined locations behind the leading edge of flashing metal, used to engage and secure the sheet-metal flashings intermittently to the adjacent substrate or another metal component.

- The NRCA recommend the edge metal extend a minimum of how many inches below the joint between the top of a wall and the wood nailer?

- 1 inch

- 45 MPH wind will raise water how many inches in conditions with little friction?

- 1 inch

- Why does the NRCA not recommend adding sealant to the edge metals drip-edge and the wall surface?

- Because it doesn’t add to the weatherproofing may prevent the passage of air and water vapor trapping moisture in the wall construction, preventing the wall from drying out.

- When designing a roof what should be kept to a minimum to prevent the possibility for leaks?

- Roof penetrations

- What is thermal movement?

- A material’s dimensional changes resulting from changes in temperature. As material experiences a rise or decrease in temperature, the material will expand or contract, respectively.

- Why is fixing a metal roof panel on both ends bad?

- Because it restrains thermal expansion causing stresses to the metal panel.

- What can a roof designer do when considering thermal expansion and the metal roof panels.

- Refer to the formula to give the expected change in length of the metal panels. That formula. The formula is Change in L = a x L x change in T. L=panel length, a=coefficient of linear expansion for steel, Change in T=Change in Temperature

- To accommodate thermal expansion clips must allow panels to ________ back and forth or accommodate ______________.

- Horizontal movement of a metal roof panel is less of an issue because ________________.

- The width is relatively small

- Flashings attached to metal roof panels, or the structure must be installed with a _______________ connection or be designed with a ______________ profile that allows the flashing to flex and accommodate the metal movement.

- Slip-type, multiple-bend profile

- How can rake edge metal flashing be installed to accommodate thermal movement?

- Fixed to the substrate and an end-panel pan clipped to or locked to engage the flashing

- Fastened to the end panel and locked to engage a continuous cleat.

- Why should metal panels be protected from standing water?

- Standing water can stain and discolor metal roof panels.

- Should the protective film on metal roof panels be removed?

- Yes, if not they can degrade the ultraviolet exposure.